The leading suture cutter

for braided polymer sutures!

Our long experience and patented technology since 1999 in building suture cutting machines allows us to give you quality guaranties: We strife to build the most reliable, stable machinery on the market. The final cut suture has very tight tolerances in diameter, roundness, pull strength and length.

Basic features

The suture-cutting and -tipping machine Fibapic can be used for most polymer sutures, including absorbable polyglycol acid, polyester, and polyethylene products. In order to avoid blooming, the machine seals the suture ends. The cutting of the suture is designed to avoid flattening, so the suture tips keep their circular shape. Neither additives nor glue are needed, making the device almost maintenance free.A dditional features include oblique cutting; knot detection; removal of insecure, stiffened suture tips; and active control of suture diameter at the stiffening area. The stainless steel case surrounding the cutter prevents dust and airflow from entering the sealing and cutting unit. The process ensures that tight tolerances are met and maintaining suture cleanliness.Optionally, the device also cuts supple monofilaments. The equipment's operating speed is higher with monofilaments than with braided sutures.

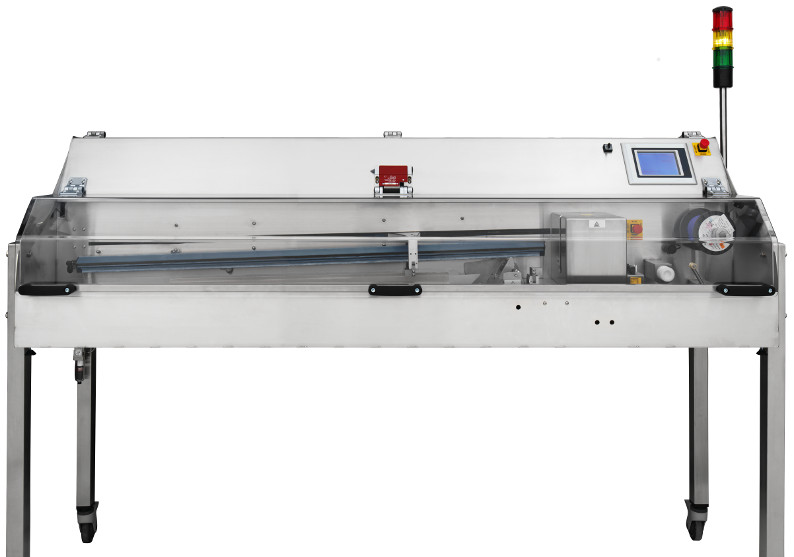

Such a maximal sized suture cutter is shown in . All suture cutters are on 4 rubber-rollers with a fixing-break on each wheel.

Certifications

Our process is controlled by the standard ISO 9001. Our company is certified ISO 9001 and ISO 13485. On demand we deliver calibration and validation of the machine according to ISO 17025.

Compliance

Complying with increasing regulatory requirements, the machine produces logging files of all products produced. Timestamps of manufacture together with serial numbers and operators name. The working process fulfils GMP standards and fits easily into the ISO 13485 and the European - MDR documentation process.

+41 79 702 58 66